Production Process Management Pain Points

Difficult SOP Supervision

Traditional methods lack effective means to supervise them, making it difficult to ensure consistent execution by operators

Difficult Efficiency Improvement

Lack of real-time and accurate data, unable to comprehensively analyze bottlenecks and optimization points in the production process

Difficult Fault Reproduction

Difficult to reproduce and troubleshoot faults in automated production, leading to stoppages and delays in the production process

Reject pure manual management methods, make factory management targeted

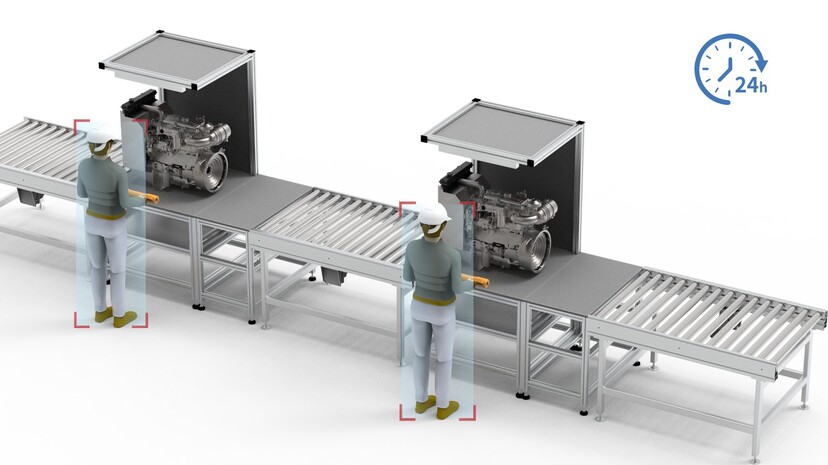

Real-time Monitoring

In traditional factory management, one production manager cannot monitor all operations simultaneously. Simmir provides solutions for 24-hour uninterrupted monitoring, even with numerous night shift operators, real-time monitoring of their behavior patterns and timely identification of violations and abnormal events. Once problems are detected, Simmir equipment automatically records abnormal situations, enabling faster discovery of product quality issues.

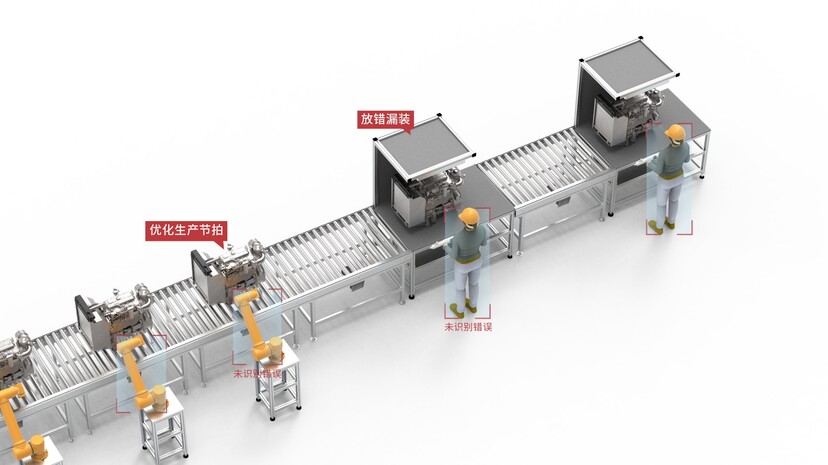

Real-time Intervention

Even with significant manpower investment in patrol and monitoring, factories cannot achieve true process behavior monitoring and abnormal event detection of workers. Through Simmir's solution, factories can achieve 24/7 monitoring, accurately detect violations and abnormal events, and issue timely warnings. Additionally, Simmir can record violation detection, comprehensively understand any violation abnormal events, while saving more management work on production lines.

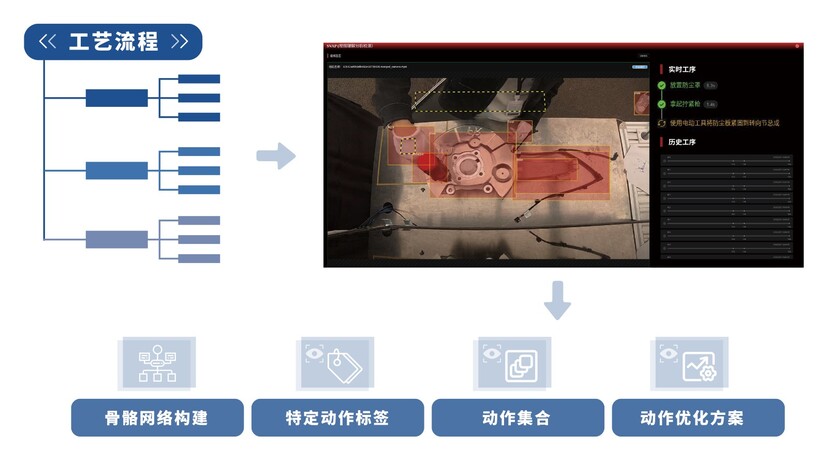

Real-time Data Analytics

To understand production process monitoring at any time to carry real-time monitoring data, enabling factories to obtain on-site data for each stage, allowing complete synchronization to improve production efficiency, enable rapid problem detection, and formulate scientific and reasonable production improvement plans.

SOLUTIONS

Higher ROI Production Line Management Approach

Reduce Product Defect Rate

Prevent skipping or missing steps through timely detection and intervention

Maintaining consistent operation actions can improve product quality stability

Improve Production Efficiency

Targeted improvement of production line layout

Reduce error probability

Reduce Equipment Failures

Real-time alerts for unknown abnormal situations in automated production

Help equipment managers solve problems promptly

Related Products

EventCAM® IR

EventCAM® IR

AI EventCAM® 2D

AI EventCAM® 2D

EventCAM® 3D

EventCAM® 3D

Related Industries

3C电子

Car Automotive

3C电子

Car Automotive

3C电子