Pain Points in Industrial Safety

Fail to Satisfy Functional Requirements

Traditional non-intelligent protection methods fail to meet the functional requirements and have lower accuracy. For example, safety sensors cannot distinguish between persons and AGVs or other movable automated devices, which cannot effectively ensure personnel safety. In addition, for the increasingly widespread collaborative robots, although safety schemes with touch-stop measures have been implemented, they can still hurt personnel.

Fail to Avoid Safety Vulnerabilities

Traditional non-intelligent methods cannot avoid vulnerabilities that pose risks to personal safety. For example, the reset operation of safety sensors from external person will restart the automatic system when other unseen persons are still in a dangerous area, resulting in safety accidents.

Fail to Trace

Traditional non-intelligent methods can only issue alerts at the time of danger, but they cannot figure out the cause of the danger or provide visual traceability. This poses a great challenge to the improvement of factory management and creates difficulties in accurately assigning responsibility for industrial accidents.

Get Rid of Insecure Human-machine Collaboration Methods and Make Production Safer and more Efficient

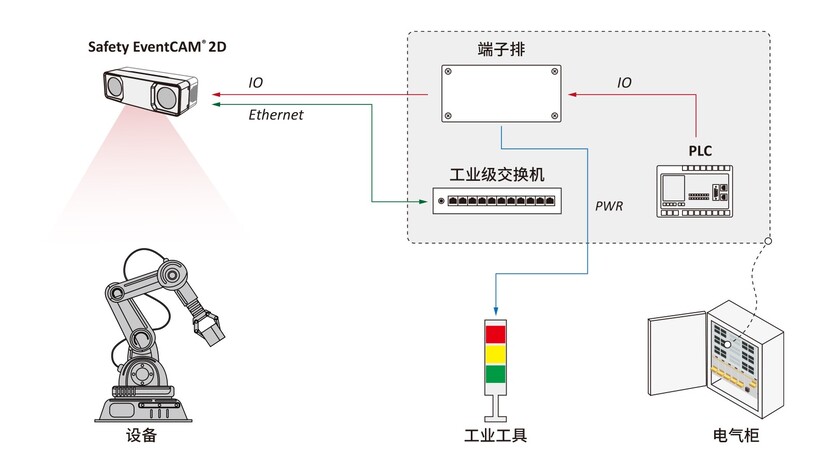

Connect to Automated Equipment Directly

SVPP can directly connect to the automation equipment. When there is a danger, the equipment can quickly identify and only react to the danger of humans (supporting the disguishing between persons and objects). It can also provide secondary alerts based on location and size filtering to control collaborative robots in performing multi-level deceleration.

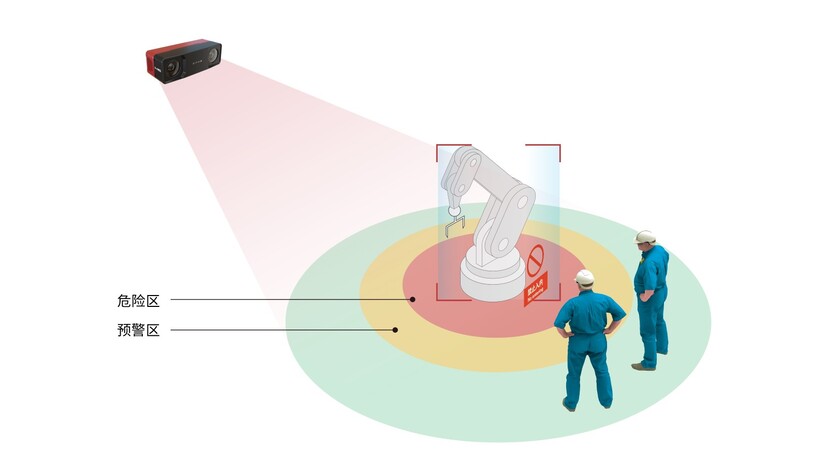

Recognize Person Accurately

SVPP can distinguish between persons and objects, allowing flexible reactions to humans, and achieving safe and integrated human-machine collaboration. -When a person enters the productive area, the robot will slow down; -When a person enters the robot region, the robot will stop operation; -When a person leaves the robot region, the robot will resume operation. In addition, Simmir's system does not support manual resetting, thus avoiding the vulnerability issue caused by misoperations.

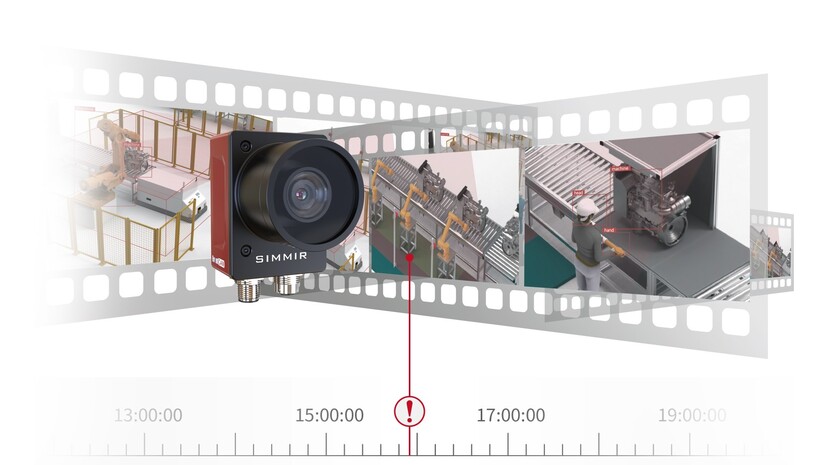

Generate Tracing Data Automatically

SVPP can immediately record video segments before and after a danger occurs, and link them with the danger alert. This allows managers to quickly reconstruct the scene, saving time for investigating the cause. The segmented video is also convenient for long-term storage and can be used as training material to improve management.

SOLUTIONS

Safer Human-Machine Collaboration

Ultra-low Response Latency

SVPP features an lower response latency, only second to autonomous driving technology. The system can quickly react when personnel enter dangerous areas and stop equipment with a response time of less than 50ms. This minimizes the movement distance of the industrial equipment, preventing collisions with personnel.

Lower Incidence of Accidents

SVPP fills the gaps in traditional safety protection methods by accurately recognizing persons, thus ensuring personnel safety. Its unique high-accuracy video understanding algorithm and redundant mechanism enable the system to accurately recognize personnel within dangerous areas, even when obstructed by equipment.

Significantly Reduce Cost

SVPP adopts an integrated design of hardware and software specifically tailored for safety detection. The product features an out-of-the-box characteristic, resulting in a significant reduction in overall costs. This allows users to economically and efficiently implement upgrades in industrial safety.

Related Products

EventCAM® IR

EventCAM® IR

AI EventCAM® 2D

AI EventCAM® 2D

EX EventCAM® 2D

EX EventCAM® 2D

Safety EventCAM® 2D

Safety EventCAM® 2D

EventCAM® 3D

EventCAM® 3D

Related Industries

3C电子

Car Automotive

3C电子

Car Automotive

3C电子